Three Phase Oil Immersed Transformer

General

Farady offers a complete range of distribution transformers designed to grant the reliability, durability, and efficiency required in utility, industrial, and commercial applications. Farady’s liquid-filled transformers are manufactured in accordance with the most demanding industry and international standards. Compliance with important standards, from IEC to VDE, is a matter of course, just as much as the exclusive use of high-quality materials. Qualified employees implement the demanding standards in daily practice.

Standard & Features

-Product Range:15kVA-20MVA, up to 44kV

-System voltage: max. 36 kVA 200 BIL

-Coolers: corrugated wall or radiator

-Oil preservation: hermetically sealed or conservator/free breathing

-Tap changer: off-circuit or on-load

-Cooling medium: mineral oil, Midel

-Steel type core clamping system

-High voltage (HV) multilayer winding

-Low voltage (LV) foil winding or layer winding

-Winding materials aluminium or copper

-High temperature class transformers

-Low noise solution

-Efficient transformers with reduced losses

-Cooling: ONAN, ONAN/ONAF, KFAF, KFW

Service Condition

a) Suitable for indoor or outdoor application

b)Air temperature: Maximum temperature: +40℃; Minimum temperature:-30℃

c) Humidity: Monthly average humidity 95%; Daily average humidity 90% .

d) Altitude above sea level: Maximum installation altitude: 2000m.

e)Max wind speed:35M/s

f) Ambient air not apparently polluted by corrosive and flammable gas, vapor etc.

g) No frequent violent shake

Note: Beyond those services condition should enquiry to manufacturer technical dept during order

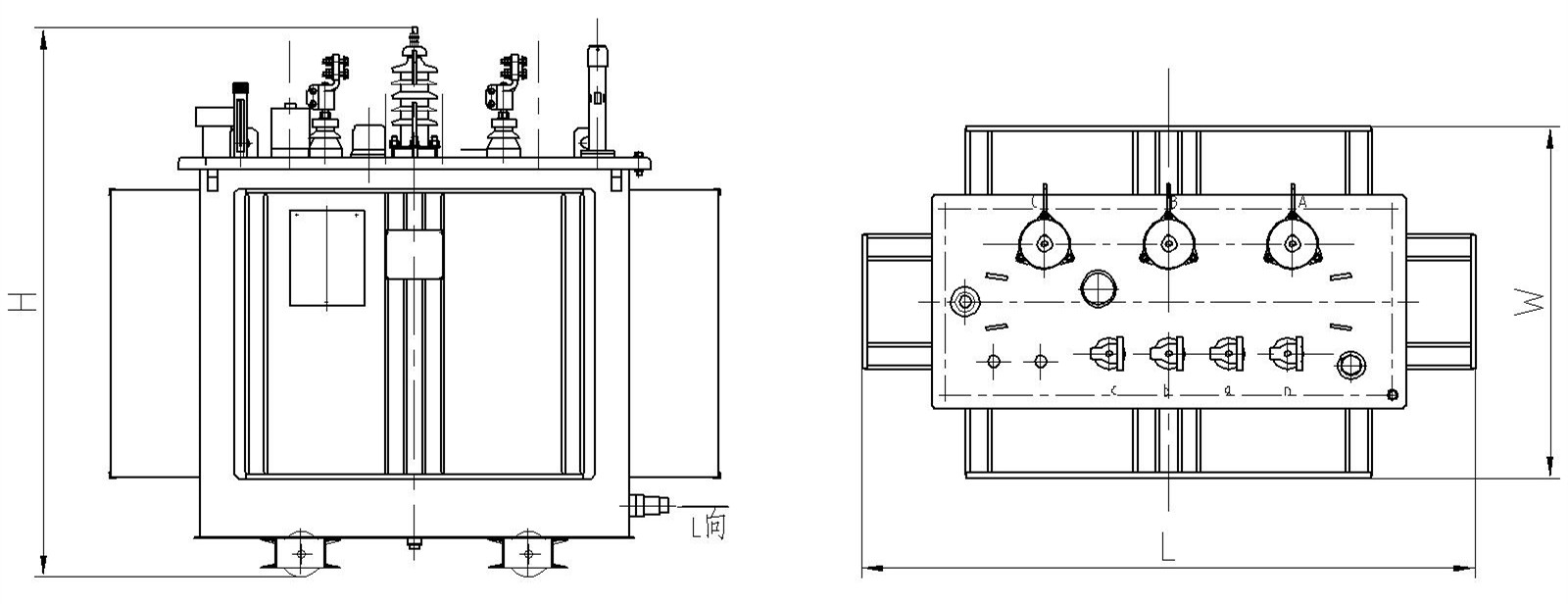

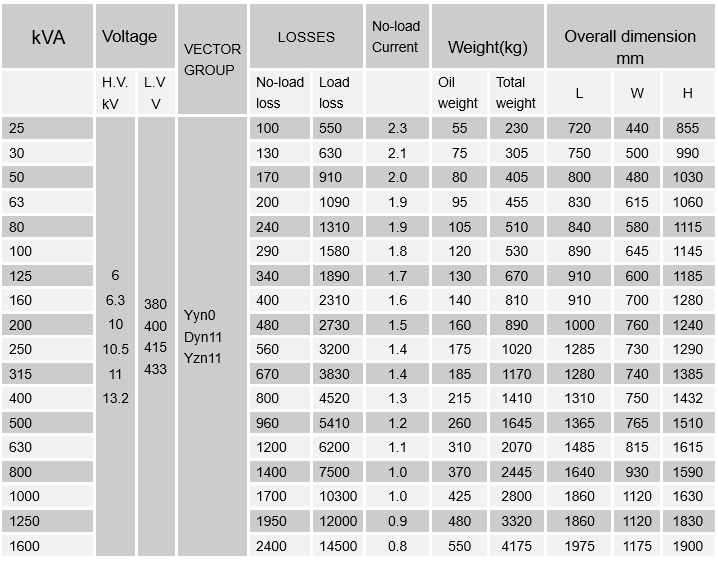

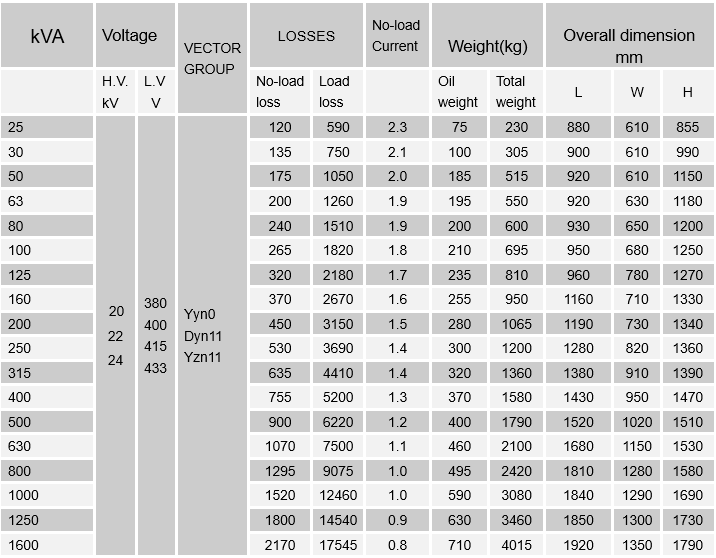

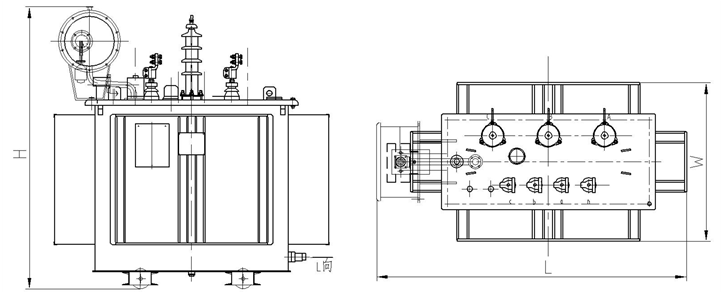

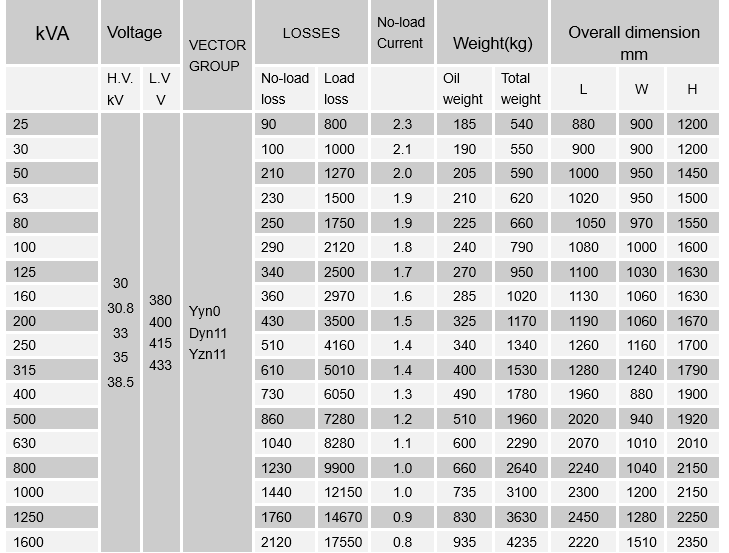

Technical Data

Factory Test

• Voltage ratio. Polarity and phase relationship test on each tapping

• Resistance of all windings

• No-load current and no-load losses measurement

• Load losses measurement at rated current and frequency

• Impedance voltage measurement

• Induced over-voltage and separate source voltage withstand tests

• Impulse voltage withstand test.

• Noise level test

• Oil leakage test

• Overload test at 150% rated current for one hour after temperature rise test and hot resistance measurement of (HV – LV)